Modern Materials, Inc.

Your choice finisher since 1975

Modern Materials, Inc.

Your choice finisher since 1975

The Modern Materials team is trained to tackle even the most complicated masking requirements.

- Hi temperature tapes and custom templates.

- Dots, Plugs, and custom fixturing

- Sharp mask lines and clean threads

Integrity

Trusted Expertise

Guaranteed Follow-through

Flexibility

Trained and Expert Staff

Continual Team Developmemt

Quality

Careful Process Control

Ongoing Process Development

Modern Materials understands that any finish is only as effective as the pre-treatment.

- Modern offers 3, 5, and 7 stage iron and zinc immersion phosphate. All tanks are heated with steam for the most effective temperature control.

- Modern operates a large rotating drum for high volume washing and de-greasing on smaller components

- Modern maintains blast capacity with one automatic tumble blast unit for small components a large manual cabinet for larger pieces.

- Modern recently added three vibratory finishing units for polishing surfaces

Integrity

Trusted Expertise

Guaranteed Follow-through

Flexibility

Trained and Expert Staff

Continual Team Developmemt

Quality

Careful Process Control

Ongoing Process Development

Modern Materials understands the importance of protecting a finish in-transit. We can store and track your pack components and assemble the pack to specification.

- Packaging per Cat 1E2001 and other standards

- RP to guard against rust on machined surfaces

Integrity

Trusted Expertise

Guaranteed Follow-through

Flexibility

Trained and Expert Staff

Continual Team Developmemt

Quality

Careful Process Control

Ongoing Process Development

Modern Materials has developed several unique processes to season cookware.

- The seasoning line utlizes a 20' gas-convection, belt-style curing oven for baking oils at hi temperature.

- The seasoning booth accommodates manual or automatic spray with a specialized HVLP gun for vegetable oils

- Processes for multi-coat, varying color, varying oil type, restoration, and seasoning on smooth surfaces have been developed over the last 2 years to address multiple applications.

Integrity

Trusted Expertise

Guaranteed Follow-through

Flexibility

Trained and Expert Staff

Continual Team Developmemt

Quality

Careful Process Control

Ongoing Process Development

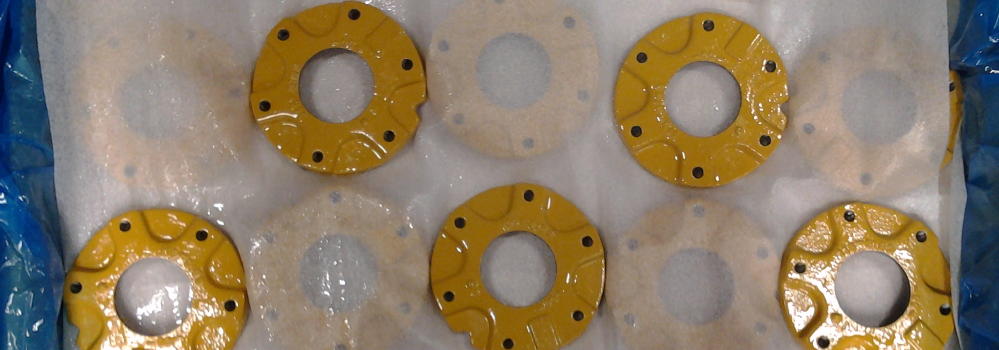

Modern Materials has capacity for fully automatic or manual powder spray.

- The automatic line, equipped with two booths, can carry parts weighing up to 160 lbs and up to 30"x24"x24" in size. The conveyor can travel up to 16 feet per minute and the gas-convection curing oven allows for 40' of curing length.

- Modern operates one manual, job shop style booth. It is 25' wide x 10' deep.

- Modern operates four batch-style curing ovens with capacity to accommodate parts up to 10'x10'x10' in size.

Integrity

Trusted Expertise

Guaranteed Follow-Through

Effective Team Work

Pursue organizational solidity and press on effective team-work

Quality Assurance

Ensure first and best of product quality and service

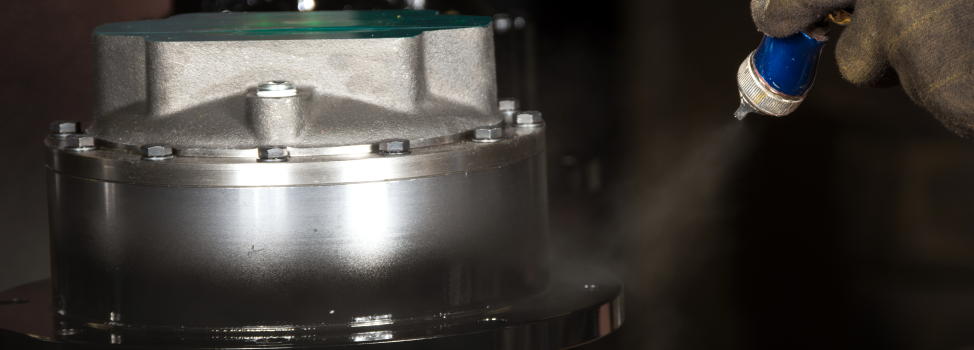

Modern Materials has capacity for fully automatic or manual liquid spray and liquid dip.

- The liquid dip line utilizes a special 150 gallon tank designed for quick change-outs and it can process parts up to 28"x 44" x 25" in size. The line can handle up to 150 lbs per drop and can turn about 60 drops per hour. The line also has capacity to join drops for a total part capacity of up to 300 lbs.

- Modern maintains three automatic HVLP spindle lines for parts ranging up to 30 lbs

- Modern operates three manual liquid booths.

Integrity

Trusted Expertise

Guaranteed Follow-Through

Effective Team Work

Pursue organizational solidity and press on effective team-work

Quality Assurance

Ensure first and best of product quality and service